The Challenge

Off road heavy equipment operates in rugged environments. Normal working conditions present real challenges for your fire suppression system. The time to find out your system doesn’t work is not when you need it. Cost associated with fire are not just monetary, your employees safety is also a great concern.

The Solution

You need a fire suppression system that is built with you in mind and a service company that understands your industry. Even though we work on all brands of fire suppression systems we only sell one, AFEX. AFEX has the engineering and design to hold up to the conditions you are going to put it through.

Steel Tubing vs Hose

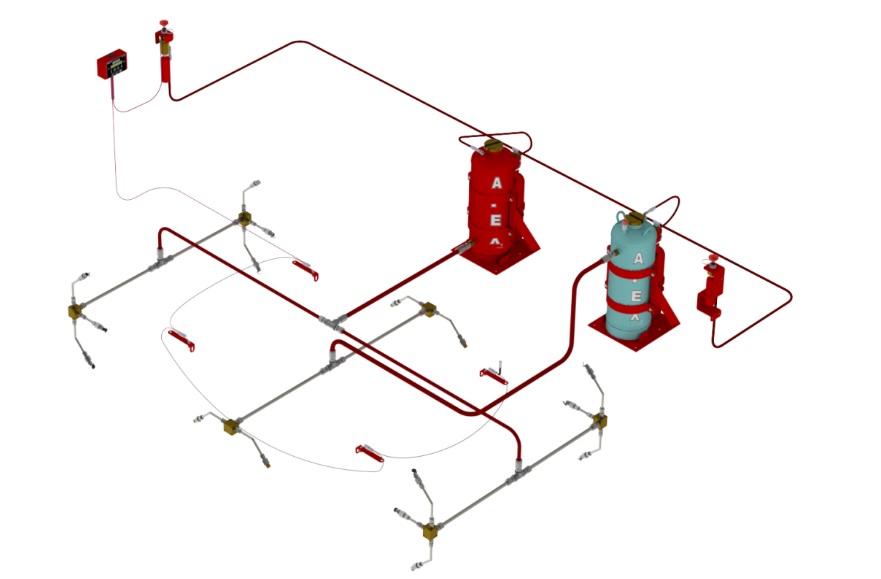

Reducing wear parts – reduce cost Worn hoses are a common repair item for system owners. This is an unavoidable issue due to the environment. The AFEX system has a unique design that significantly reduces the number of hoses used on a system. Cost associated with fire are not just monetary your employees safety is also a great concern. When caps become missing the orifice can become clogged. The AFEX nozzle has a hinged metal cap that holds up very well in the extreme heat of the engine and transmission areas of the vehicle.

Reduce Total Cost of Ownership

Reducing wear parts not only reduces cost but it reduces potential failure of the wear part. They are called a “wear part” after all. Our nozzle caps are permanent and much of our chemical transfer lines are made of steel.

Train your Team

No matter what brand of fire suppression system you have on your equipment, it is a good practice to perform a pre-shift inspection before starting your work day. In the normal course of operation hoses can become loose, nozzles could get damaged, cartridges can be taken off for maintenance and not replaced as well as many other things. A knowledgeable operator can spot trouble before it happens. Identifying issues with the system before it needs to discharge in the event of a fire definitely saves property and potentially saves lives. We will come to your site to train your operators and mechanics. Give us a call at 1-844-455-5777 to set up a class.